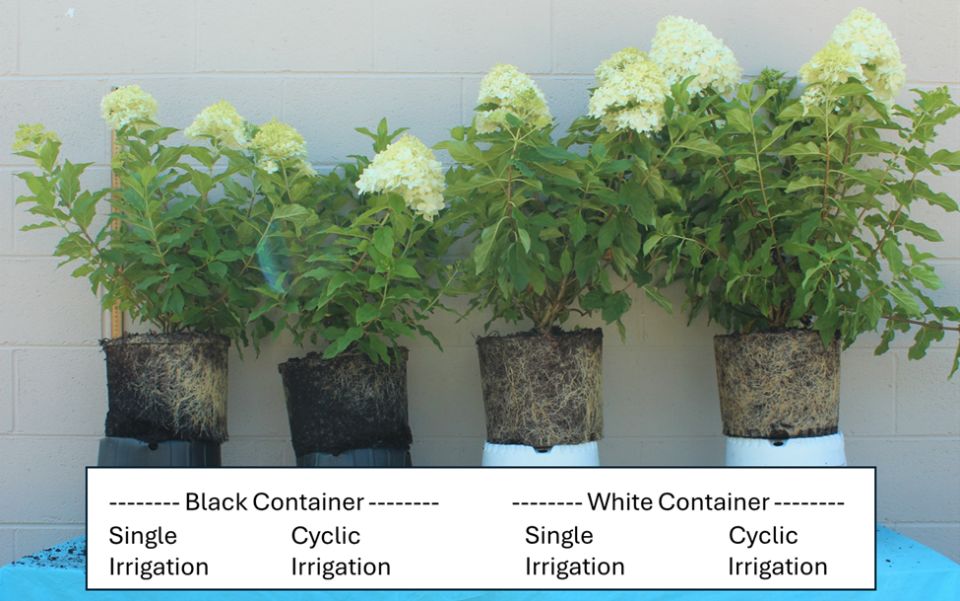

A frequently observed example of direct injury due to extreme root temperatures is uneven rooting. In this case the northern exposure of a root system grown in a black container (temperature unmanaged) vs. a white container (temperature managed) shows the difference in root quality that substrate temperature management can have. Photo: Jeb Fields

While we all physically feel the effects of the hot weather, we often overlook the effects of high temperatures on plant material. It is common to protect plants from winter’s chill using frost protection methods. After all, if temperatures get too cold (particularly in the roots), the plant will die. For many, this is the extent of temperature management. But extreme heat creates stark issues too, albeit less immediately apparent.

Take, for example, the day following a harsh freeze, where susceptible, unprotected plants are visibly damaged by the frozen temperatures. Susceptibility to high temperatures is not as immediate, and the effects often take time to build before damage is observed.

The root system regulates much of the plant’s health. Research has shown that indirect injury occurs when substrate temperatures reach 104°F for extended durations (five to six hours). This can be subtle and involves the cessation of growth, impairment of hormone signaling, inhibition of nutrient uptake, and increased disease occurrence.

Direct injury, a much more severe issue, can occur with more excessive temperatures at much shorter durations (as low as 20 minutes). Extended exposure to extreme temperatures can eventually damage root systems beyond repair and result in poor health and aesthetic quality of plant materials. With direct injury, plants experience symptoms related to indirect injury, and can begin to die back, particularly in the roots.

We have known for decades that temperatures within containers can become extreme, with devastating effects on plant health and quality when sustained for long periods of time. While concerning, this issue did not receive necessary consideration in the past, as there was less imminent danger, and less feasible options existed. However, as the planet warms, we see more heat stress and associated crop damage across the country, even in areas with milder climates. Discussions with growers have reflected a renewed interest in combatting extreme temperatures.

Potential Solutions

There are many options at our disposal to mitigate extreme substrate temperature, some more feasible than others. Incorporating shade into production is likely the most straightforward method; however, this can be costly, especially if dealing with large areas. Implementing a pot-in-pot system, which involves a socket pot buried in the ground, leverages the natural ability of soil to insulate temperatures; however, this can be costly and inappropriate for low-lying areas prone to flooding or excessive moisture retention (i.e., see Louisiana). Furthermore, in-ground installations involved with the pot-in-pot method restrict the re-arrangement options for plant spacing.

There are several management practices that can be more readily implemented to help alleviate extreme swings in substrate temperatures.

Irrigation can serve to cool plants and the substrate when managed with temperature mediation in mind. Cyclic irrigation application (i.e., splitting applications throughout the day) has been shown to moderate temperatures. However, irrigating in the afternoon can only offer so much respite from the heat, lowering the temperature by just a few degrees in extreme cases. If pipes are exposed, the water coming out will be hot and counteract much of the cooling. Moreover, watering in the heat of the day typically runs counter to recommended best management practices.

The biggest concern of all? Application of too much water to control temperature can have adverse effects for crop growth. Recent research from Auburn University shows how tightening the spaces between containers will help shield them from direct solar radiation and provide some additional shade, limiting the access direct sunlight has to container’s surface. Despite the benefits of spacing management, this option can be inconvenient, as plants may need to be regularly respaced and shuffled around over time.

‘Limelight’ Hydrangea paniculata grown at Louisiana State University Agricultural Center. Notice the improvements in both root and shoot (foliage) with temperature modification. Photo: Jeb Fields

While these actions to combat high temperatures have their benefits, another option — container color — is becoming more commonplace in our industry and can significantly reduce substrate temperatures. The industry standard black container commonly seen in nurseries is efficient at absorbing solar radiation in the form of heat and warming the substrate within.

In a typical summer, the substrate temperature in these pots regularly reaches more than 100°F; however, in hotter years, we measure substrate temperatures above 150°F! There is a growing number of branded plants being produced, many of which come in lighter, more vibrantly colored containers to stand out among the bevy of black potted plants. These containers can mitigate extreme substrate temperatures.

In 2022, our team at the LSU AgCenter evaluated plants grown in white vs. black containers. On average, black containers exceeded the 100°F critical temperature for about nine hours a day, while the white containers exceeded 100°F for less than two hours. Remember that indirect injury is a result of duration over the critical temperatures. So, while high temperatures may be unavoidable, efforts to reduce the duration is time well spent. In fact, over the entire summer, the white containers were more than 100°F for less than half the time of the black containers. That is effectively reducing any exposure to heat-stress by 50%, conservatively.

The white containers also reduced the average maximum daily temperature by about 9°F. Of course, there were extreme events, but 9°F is a very large window when exploring temperature stress. Don’t believe us? Set your thermostat to 9 degrees warmer and see if anyone notices.

What does this temperature difference mean for production? Healthier and more vigorous plant materials.

White containers are becoming more available through many suppliers. For growers not interested in branded plant materials, you can still secure blank white containers to mitigate temperatures. It is critical to remember that when using alternative containers, you need to ensure that you are using black-interior containers. This lining limits light penetration to the root zone, which can hinder root growth and result in algal growth.

Another cost-effective and extremely beneficial practice is simply monitoring. As the adage goes, knowing is half the battle, and knowing your substrate temperatures will certainly help with decision making.

There are various ways to monitor substrate temperatures. A handheld probe can be stuck into a container and easily read temperature to spot check. For the more tech-savvy growers, sensors can be placed within containers. These can be wired or simply buried in the container to wirelessly transmit temperature, and other metrics, to your phone or computer.

The agricultural industry is becoming more technologically advanced, and temperature monitoring, management, and mediation is a cool area to explore with little associated costs.

This article was co-written by Jeb S. Fields, an Associate Professor and Coordinator of the Hammond Research Station at the Louisiana State University (LSU) AgCenter; Ashley Hickman, a graduate student in the Fields Lab; and Damon Abdi, an Assistant Professor at the LSU AgCenter.